X-ray sterilisation

- Category: News

The development of single-use sterile systems, encouraged by changes in good manufacturing practice (GMP), and the fallout from the COVID crisis are leading to a significant increase in the volumes sent for sterilisation. This need is unlikely to decrease in the coming years, and is putting pressure on those involved in product sterilisation, particularly gamma irradiation sites.

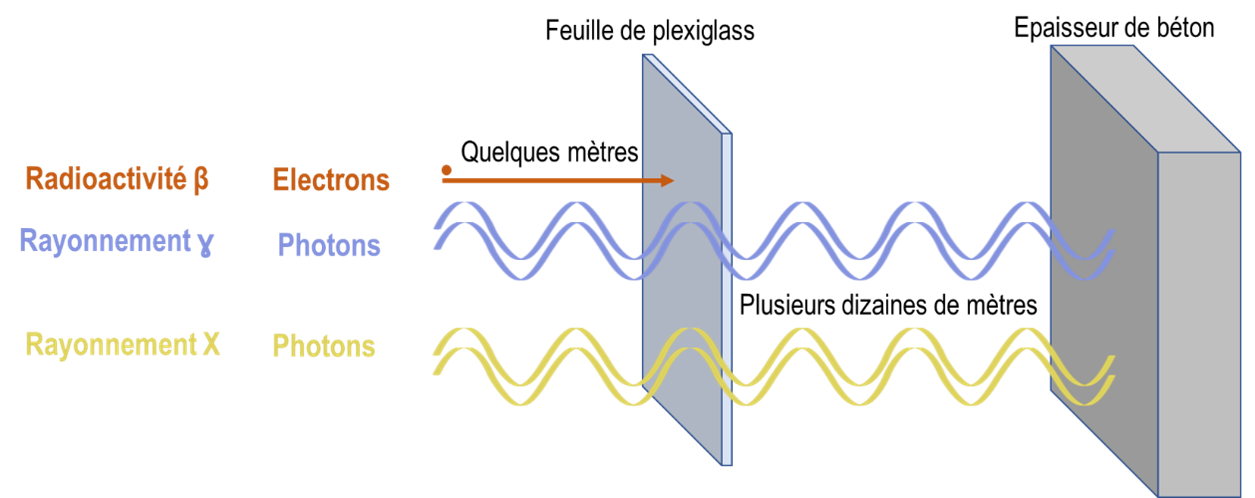

This situation is leading manufacturers to evaluate other sterilisation techniques. Wet or dry heat techniques are not always suitable for plastic-based products, even though they are the methods recommended in good manufacturing practice; and sterilisation by Beta radioactivity is not suitable for dense liquid products and is preferable for products such as solid medical devices. Of all the techniques available, sterilisation by irradiation with X-rays could make up for the lack of capacity in gamma radiation sterilisation.

What are the differences between X-rays and Gamma rays?

From a physical point of view, X-rays and gamma rays are similar, with relatively similar wavelengths (10-14 m to 10-12 m for gamma rays and 10-12 m to 10-8 m for X-rays). They both penetrate matter well, and the dose absorbed is expressed in Gray in both cases.

Although the appearance and effects of X-rays and gamma rays are similar, the way they are produced and their impact on the industrial process are very different. Gamma rays are generated from Cobalt 60 (60Co) rods, a radioactive product that is difficult to obtain, highly regulated and only available from a limited number of suppliers. These rods, which have a lifespan of around 5 years, constitute a radiation source that needs to be replaced and requalified regularly. X-rays are generated using an electrically powered electron gun, and the flow of electrons is converted into X-rays via a tantalum plate. The source is then stable and virtually inexhaustible. A set of magnetic fields is used to obtain a unidirectional source. This orientation of the source reduces the number of times the pallets pass in front of the source, thereby reducing pallet processing time.

The similarity of action and the advantages linked to the characteristics of X-ray generation make them a good alternative to Gamma-ray sterilisation, despite their limited deployment in Europe at present.

The introduction of X-ray-treated systems into industrial processes as a replacement for gamma-ray-treated systems requires an in-depth analysis of the impact of the change, with an assessment of the effects of X-rays on the intrinsic characteristics of the systems, on their characteristics in use and an evaluation of the effectiveness of the sterilisation.

What is Conformat's response to X-ray sterilisation ?

Conformat is aware that these changes need to be accompanied, and has undertaken to qualify the impact of X-rays on the products in its ranges in order to meet its customers' expectations.