Surface Disinfection by Air (DSVA)

- Category: News

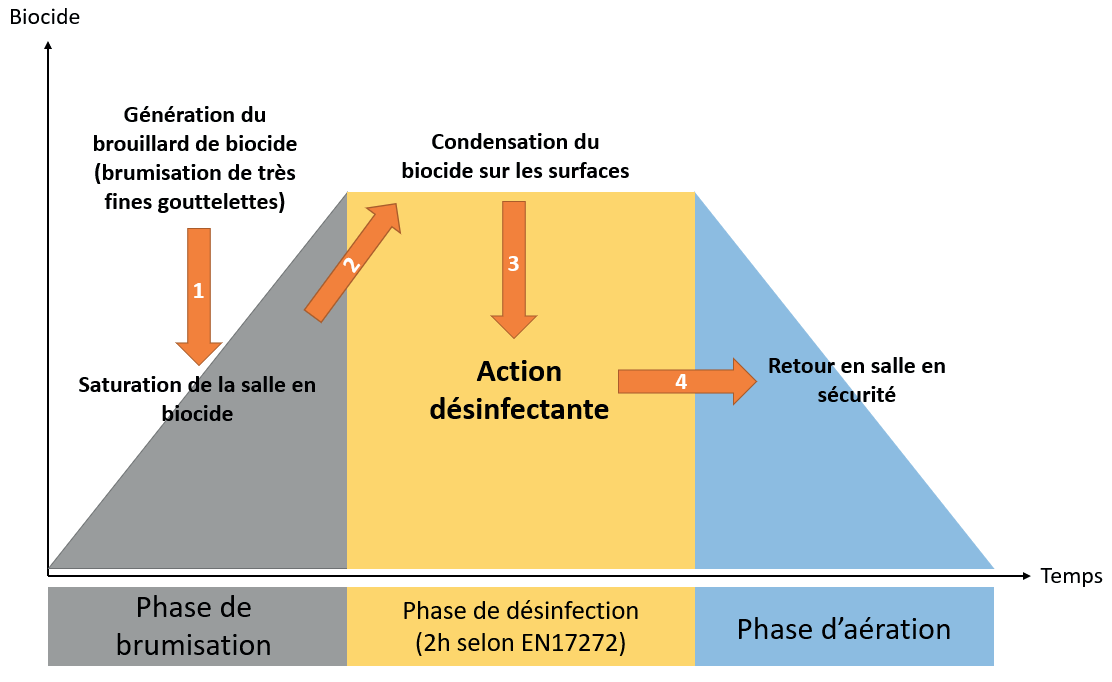

Aerial surface disinfection (ASD) is a method of disinfecting surfaces by dispersing a biocide in a sealed room. This process reaches all surfaces, even the most inaccessible, in a defined cycle. An example of a misting cycle is shown below:

DSVA enables a biocide to be dispersed in the form of a mist or gas. The product then micro-condenses on the surfaces, disinfecting the entire exposed area. This microcondensation is not the same as wetting the surfaces. The wetting effect should be avoided (deterioration of certain cleanroom components, evidence of poor diffusion of the biocide).

The main advantage of DSVA technology is that it ensures safe, repeatable disinfection of all surfaces, considerably reducing human involvement and the amount of biocide used in this stage.

In particular, the pharmaceutical industry uses this process to carry out "clean-ups" - critical stages in the return to a given level of cleanliness following contamination, a scheduled maintenance action or a continuous, defined and validated period of production or, conversely, inactivity. In rarer cases, it can be used as a standard routine disinfectant for the reference environment.

The biocide used most often contains hydrogen peroxide (H2O2). This active substance provides broad-spectrum disinfection (bactericide, yeasticide, fungicide, sporicide and virucide).

The active ingredient in question is stabilised H202. This is sometimes combined with peracetic acid to create a chemical synergy (attacking the constituent sites of micro-organisms in different places).

Finally, other formulations use quaternary ammoniums as the sole active ingredient or, again, in combination with H202.

At Conformat, we recommend biocides based on stabilised H202 with the lowest possible quantity of co-formulants. H2O2 is known for its dismutation into water and oxygen, making it a biodegradable active substance with a very low level of residual contamination. What's more, these biocides protect surfaces and guarantee low levels of oxidation over time. Finally, their proven effectiveness is comparable to that observed with products combining peracetic acid and H2O2.

In regulatory terms, the recent publication of standard EN17272 has redefined the proof of efficacy of machine/product combinations. The French standard NF T 72-281, replaced by the new European standard, did not take into account the homogeneity of the biocide distribution.

As a reminder, these standards do not cover the biocide or the DSVA machine separately, but rather the action of the biocide combined with the machine process. This is referred to as the machine/product pair. This is no longer valid if the biocide or the machine is replaced.

However, the tests in accordance with EN17272 are carried out in typical spaces; the guarantee of the effectiveness of the DSVA process for your spaces remains the performance qualification (PQ)!

In this respect, it is important to mention that the size of the biocide droplets is not the only factor determining whether one DSVA is more effective than another.

In fact, the DSVA process is influenced by a large number of parameters (dispersion of the biocide, fogging time, contact time, temperature and hygrometry of the room, initial cleanliness of the surfaces, etc.). We strongly advise you to contact your supplier for further information.

This diversity of factors influencing the effectiveness of DSVA can lead to misunderstandings and technical biases (increase in maximum capacity, log 6 disinfection not standardised but claimed, danger of biocides underestimated, etc.). Don't hesitate to challenge suppliers on the suitability of their DSVA process for your facilities.

In addition to their proven effectiveness, DSVA machines appear to be increasingly automated and connected. The efficiency of the machine/product pairing and the associated performance are no longer the only customer requirements. Simpler, faster and safer cycle start-ups, a rigorous audit trail and traceability in compliance with CFR21 part 11, and compliance with increasingly demanding HSE requirements are all new criteria that need to be met.

Conformat remains at your disposal to help you integrate a DSVA system into your cleaning programmes and maintain cleanliness levels. Don't hesitate to contact us !